The shortage of raw materials is affecting the entire industry worldwide, in some cases bringing it to a complete standstill. Production lines have to be stopped, in some cases even entire production facilities are temporarily closed. The assembly lines come to a standstill and the employees are sent home until further notice. And all because there is simply a shortage of resources and raw materials.

Price explosions and deliveries that are months late are just two of the consequences. Fuel prices are more expensive than ever, ordered goods arrive too late or not at all. The huge carousel of the global economy is beginning to totter. Once it is out of balance, it will probably take years to return to its original state. Many blame it on the corona pandemic. But the reasons are more diverse.

Our print shop is also a manufacturing company and we are also dependent on raw materials and material supplies. We are also clearly feeling the effects of the shortage of raw materials. We wait for paper and other materials, sometimes in vain.

What are the causes of the shortage of raw materials?

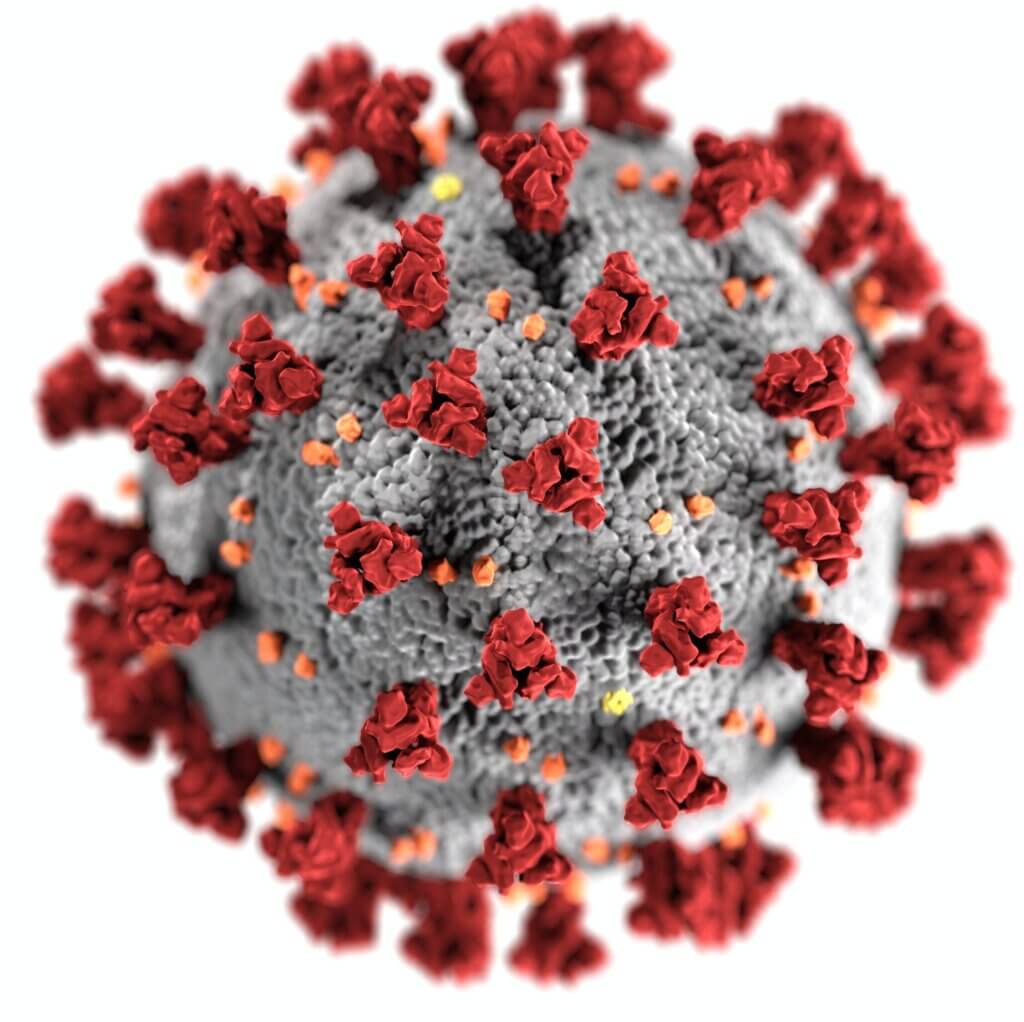

The beginning of the shortage of raw materials is probably actually due to the pandemic. As a result, the demand for various raw materials fell drastically at the beginning of 2020 – including the demand for paper. Production companies reduced capacity and cut staff. Although demand has picked up again significantly in recent months – it is even rising rapidly – paper and pulp manufacturers are unable to ramp up production at the same pace. The result: demand is greater than production capacity. Products are becoming scarce and prices are rising.

In addition to the effects of the pandemic, pandemic-independent factors can also be observed. The key ones for the paper industry are as follows:

👉 Extensive capacity shutdowns of machines for the production of wood-containing coated papers and the associated increased demand for wood-free papers

👉 Container shortage: not least the blockage of the Suez Canal has led to considerable disruptions in shipping freight traffic. The consequences are a shift in capacity from Asia back to Europe on the one hand and considerable price increases due to higher transportation costs on the other.

👉 Procurement shortage for the paper industry itself: if you have difficulties obtaining raw materials, you cannot produce and supply your own customers.

👉 An increase in demand in China leads to export bottlenecks to Europe.

👉 The boom in online retail has resulted in an increasing demand for packaging and shipping materials.

Price increases of up to 100

The shortage of raw materials is not only driving up prices for the end consumer. Intermediaries and production companies are also faced with considerable price increases. Added to this are rising energy prices and therefore an increase in the energy cost surcharge.

The price increases are passed on from production companies to paper wholesalers and printers – in some cases retroactively for orders that have already been placed. Print shops have no choice but to follow the price increases and purchase raw materials at a significantly higher price. Not all price increases can be borne by the end customer.

What will happen next?

There is currently no sign of the shortage of raw materials easing – on the contrary. Further price increases are expected in the new year. It will not be possible to significantly shorten delivery times.

Is the solution an increased use of alternative raw materials such as sustainable materials? Is the solution to reduce overtime, perhaps in conjunction with short-time working? Nobody can really answer these questions at the moment. Many companies are focusing on increasing stock levels, stability in supplier relationships and more flexible production planning. Reducing overtime and temporarily shutting down production lines are also part of various solution concepts.

Thank you to our customers in the publishing houses for showing understanding for the situation. We cheer each other up in the knowledge that we will get through this time together too. Because we know: You show strength in a crisis. We are looking forward to the time afterwards and to being able to shout to ourselves – we’ve made it!

A thank you to our employees

It is not only our company that is significantly affected by the current situation. Above all, our employeesbear the brunt of the difficult working conditions. Every day, they do everything they can to get the best out of their work and battle against difficult material procurement, delayed delivery times and a lack of transportation options.

We say THANK YOU to our employees with a small gift basket!

Thank you for your commitment, thank you for your perseverance, thank you for the determination with which you fight your way through everyday working life every day. 🖤