As a leading company in the field of high-quality print products, we have a wide range of modern printing machines at our disposal. This includes offset printing presses, digital printing presses and the extensive machinery in our bookbindery.

Why does Beltz Grafische Betriebe purchase new machines?

In the past, our machines in our print shop and bookbindery in Bad Langensalza were used for the production of large print runs, e.g. of catalogs or books. Nowadays, the classic mail-order catalog is less important and books are usually produced in smaller print runs. As a result, we have more orders for smaller print runs. Added to this are the possibilities of modern digital printing, which require new processes and intermediate steps. In order to continue to strengthen and expand our core business of thread-bound hardcovers, we are continuously adapting our machinery to the new challenges, as we did last year. You can find out which ones have been added at the end of the article.

Which machines are already in our print shop and bookbindery?

Offset printing presses are mainly used for printing large print runs of catalogs, brochures and other printed products. They work on the principle of indirect print transfer, in which the ink is transferred from a printing plate to a blanket roll before being applied to the print medium. This process makes it possible to achieve high quality at a high printing speed.

The digital printing presses in our print shop are mainly used for printing short runs of books, magazines and other print products. They work according to the principle of direct print transfer, in which the ink is applied directly from the machine to the print medium. This process makes it possible to print short runs quickly and cost-effectively without having to produce printing plates.

At Beltz Grafische Betriebe, we rely on a combination of modern printing presses and experienced printing professionals to produce high-quality print products for our customers. We always strive to optimize your processes and offer environmentally friendly solutions.

Our bookbindery has various machines for processing printed products, such as folding, cutting, collating and thread sewing machines. There are also other machines for finishing, such as the book line, perfect binding machines and gluing lines.

These new machines have moved in with us

The machinery at Beltz Grafische Betriebe is a changing area. Many of our long-standing employees can confirm this. We are constantly striving to develop ourselves further and guarantee the best quality for our customers.

What are the advantages?

- Increasing efficiency: New machines increase our production capacities and speed up the manufacturing process. This can help to increase efficiency and reduce costs.

- Improving quality: The quality of the printed products produced is improved by investing in new machinery for the print shop or bookbindery.

- Expansion of the range of services: The acquisition of new machines expands our range of services and strengthens the existing one.

- Replacement of older machines: In some cases, it may also be necessary to replace older machines that no longer work reliably or that no longer meet current technical standards.

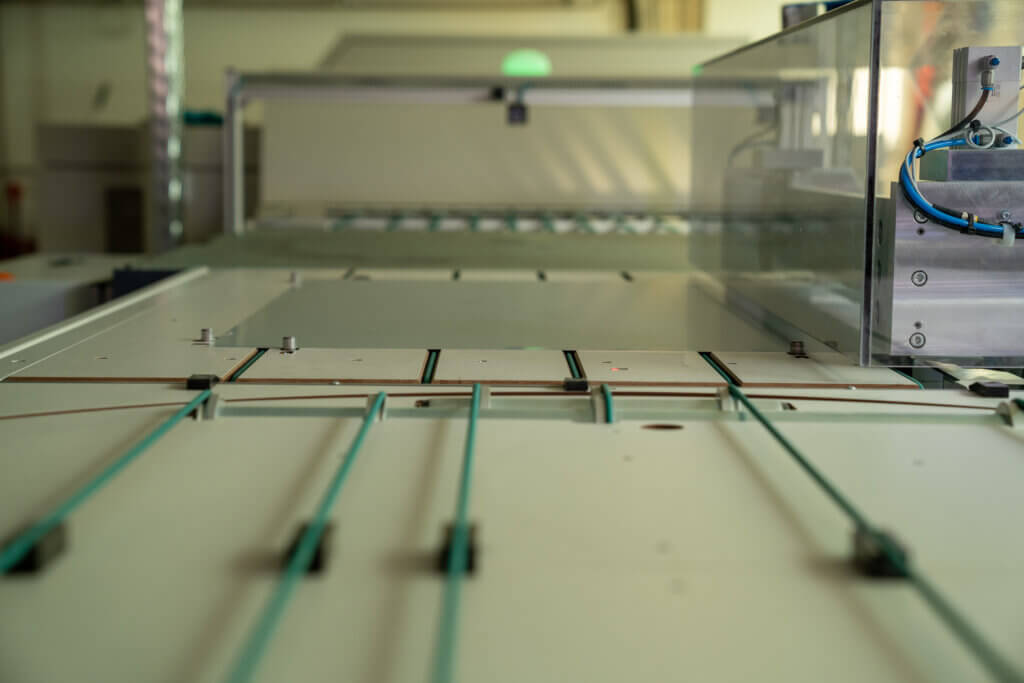

A new drawing tape machine

We have recently invested in your machinery: In a new drawing ribbon machine from the manufacturer Muller Martini, type Ribbon, put into operation. This machine makes it possible to insert up to two character ribbons into the book and was integrated into the Kolbus book line, which now forms the new main production line in the hardcover area.

The purchase of this machine has many advantages for Beltz Grafische Betriebe. This allows us to keep up with the trend of the times, which entails smaller print runs with an increasing number of orders. The machine is characterized by shorter set-up times and high reliability. This will allow us to continue to focus on our core business, the production of hardcover books, and further expand this for our customers.

Two new additions in the field of thread sewing

Two more machines have joined us in the field of thread sewing machines from the manufacturer Muller Martini, type Ventura MC 160. These machines make it possible to produce thread-sewn book blocks with a focus on smaller print runs. Just like the ribbon, the thread sewing machines are characterized by their high reliability, which results in less downtime.

The first machine was installed in 2022, while the second machine was put into operation in January 2023. The purchase of these machines is a valuable investment for us, enabling us to increase our production capacities and thus further strengthen our core business.