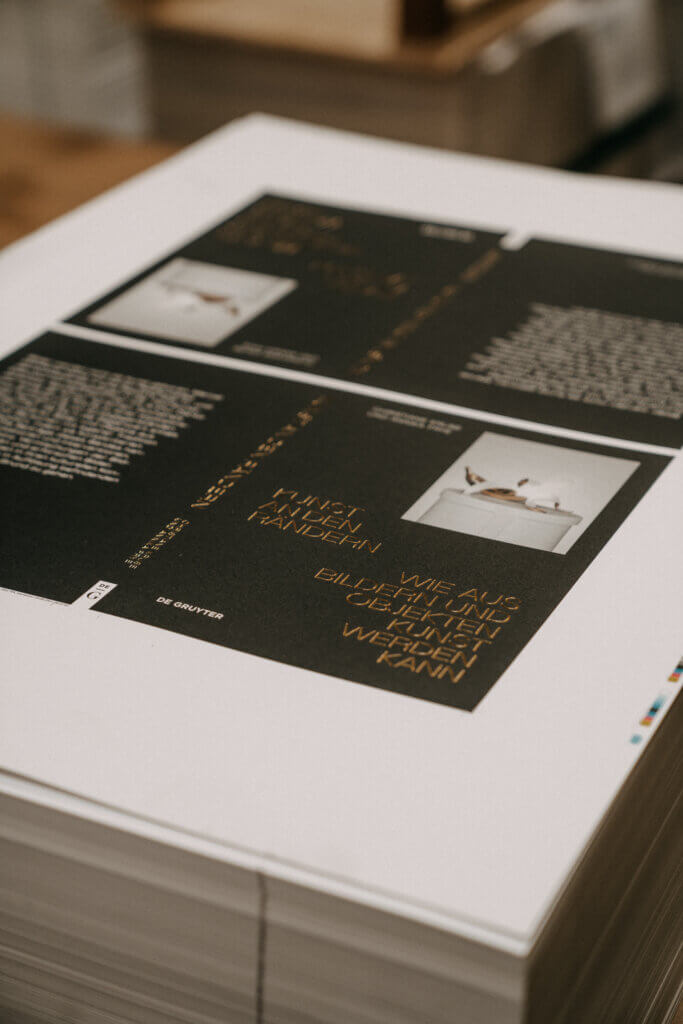

The world of printing is characterized by competition that is constantly evolving and poses new challenges. At the center of this dynamic is a printing technology that has been considered indispensable for decades: offset printing. As one of the most efficient and powerful printing processes, it has proven to be indispensable in large print shops. The process is also firmly anchored in the range of services offered by Beltz Grafische Betriebe.

The offset printing process has proven to be one of the most established and important technologies in the printing industry. With its extraordinary precision, speed and efficiency, the printing method developed into one of the most important for use in large print shops.

But what exactly is behind this complex and multi-layered printing process? In today’s blog article, we will take a closer look at how offset printing works, review its history and take an in-depth look at its applications, advantages and disadvantages. We will also look at the challenges facing the printing process today and give an outlook on how this traditional printing process will develop in the future.

The importance of print in today’s world

For many of us, printing has become commonplace and taken for granted in our digital world. Whether for professional or private use, it has become an integral part of our everyday lives. But which printing processes are there and which are suitable for which purpose? One of the most important and oldest printing technologies is offset printing.

In contrast to digital printing, where the ink is applied directly to the paper, offset printing is done indirectly. The printed image is first transferred to a printing plate, from there to a blanket cylinder and finally to the paper. A high print quality is achieved, as the paper is smoothed by the blanket cylinder, enabling even ink distribution.

The process is particularly suitable for large print runs and is therefore often used in large print shops. Thanks to the precision and speed of the manufacturing process, even complex print jobs can be completed quickly and reliably. Compared to other printing processes, offset printing is often more cost-effective due to its high efficiency and productivity.

Overall, offset printing is a proven and reliable process that has its place in both commercial and private print production.

Offset printing in focus

A look into the past of the printing process

The history of the printing process goes back to the 19th century, when there were no modern printing presses. At that time, artwork still had to be transferred to the printing block by hand before it could be printed. Over time, the technologies were improved and refined until the offset printing process we know today was finally developed.

An important milestone in the history of the process was the invention of flat printing plates. These made the printing process much simpler and more efficient, as they could be produced much more quickly and easily than traditional printing blocks.

Today, offset printing is one of the most widespread and popular printing technologies in the world. With its numerous advantages such as high quality, precision and efficiency, it is used in many areas. Whether in the advertising industry, in the production of magazines and books or in the production of packaging materials – offset printing has established itself as one of the most reliable and versatile printing technologies.

How does offset printing work?

Offset printing is referred to as an indirect printing process. The print image is first transferred to a printing plate and then printed onto the material. The process is based on the principle of the repulsion of water and grease, which is crucial for the two most important components of the printing process, namely the ink and the dampening solution.

The printing plate consists of a mostly metallic surface coated with a thin layer of light-sensitive material. The printed image is created by exposure with a special template or by electronic transfer. The light-sensitive material is hardened at the exposed areas and thus forms the printing form.

In the next step, the plate is moistened with a fountain solution, which moistens the non-printing areas of the plate and thus prevents ink from adhering to these areas. The dampening solution does not adhere to the printing areas, as the light-sensitive layer has been hardened and is therefore grease- and ink-absorbent.

The ink is then applied to the plate and only adheres to the greasy areas of the printed image. The excess dampening solution and paint are wiped off using rubber cylinders. The blanket cylinder ensures that the print image is transferred from the printing plate to the material without smudging or shifting.

Due to the indirect transfer of the print image, the process is particularly suitable for large print runs. It offers high color accuracy, sharp detail reproduction and precise image positioning. Offset printing is used for a wide range of products, such as magazines, catalogs, brochures, packaging and many more.

Since March 2021, Beltz Grafische Betriebe has been pursuing a special project to make offset printing, and therefore our entire production, more environmentally friendly. Since then, we have been using processless printing plates, which enable us to achieve considerable savings in water, chemicals, residual chemical disposal, gumming and energy.

Digital printing vs. offset printing?

As mentioned above, offset printing offers a number of advantages. It is characterized in particular by high print quality and a very precise print image. The suitability for large print runs results from the durability of the printing plates.

In contrast, other printing processes, such as digital printing, are better suited to smaller print runs. Here, the print quality is often not as high as with offset printing, but digital printing is more flexible and can also produce small quantities quickly and cost-effectively.

Another advantage of offset printing is the wide range of materials that can be printed on. In addition to paper and cardboard, plastics, metals and wood can also be printed. The use of special colors, such as metallic inks, is also possible with offset printing.

Compared to other printing processes, offset printing has a longer production time. Offset printing is more time-consuming and therefore more expensive due to the production of the printing plates and the set-up of the printing presses. The use of special colors and special materials can also increase the price.

Conclusion and outlook

In summary, it can be said that offset printing is still one of the most important printing technologies in the printing industry due to its high print quality and cost-effectiveness. It offers numerous advantages over other printing processes, particularly for larger print runs and demanding print projects, which is why it is also highly valued at Beltz Grafische Betriebe.

By using printing plates with a special ink-repellent coating, offset printing can transfer even the finest details and color gradients precisely onto the print medium. In addition, the use of special inks and varnishes can achieve effects that are not possible with other printing processes.

Offset printing is also impressive in terms of cost-effectiveness and efficiency: thanks to the use of fast printing presses and automated processes, even large print runs can be produced quickly and cost-effectively. Offset printing is also suitable for a wide range of print media.

In the future, the integration of digital technologies and the use of cloud-based solutions will make offset printing even more efficient and user-friendly. The development of new environmentally friendly materials and inks will also continue to make offset printing an important and sustainable printing technology.

In summary, it can be said that offset printing continues to play a central role in the modern printing industry due to its high quality, cost-effectiveness and versatility. Through further innovations and investments in sustainability and environmental protection, the process will continue to play an important role in the production of high-quality print products in the future.